Vi använder cookies för att göra din upplevelse bättre. För att följa det nya direktivet om e-integritet, behöver vi be om ditt medgivande att sätta cookies. Läs mer.

FREQUENTLY ASKED QUESTIONS

FREQUENTLY ASKED QUESTIONS

FREQUENTLY ASKED QUESTIONS

EMISSIONS AND STREET LEGAL STATUS

Yes, K&N® replacement air filters are emissions legal in the United States.

Intake systems are regulated parts, and not all intake systems can be used in California on pollution-controlled vehicles. As a result, K&N® sells intakes that are legal in all 50 states, legal in 49 states (excluding California), and legal only for racing vehicles. 49-state legal intakes cannot be used on pollution-controlled vehicles in California. 50-state legal intakes are legal for use in all 50 states, including California. Racing-only intakes are only for racing vehicles, and may never be used, or registered or licensed for use, on a highway. K&N makes more 50-state legal intakes than any other aftermarket parts manufacturer.

To determine if an intake kit is CARB exempt for your vehicle, use the vehicle search bar to find available intakes for your vehicle, and then select the part number. A product detail screen will open indicating the CARB exemption status for the intake and vehicle application. For more information on CARB requirements, please visit the CARB website.

If you need a replacement E.O. sticker/decal, please fill out this request form and return it to K&N® via email or traditional mail. Full instructions can be found on the form.

Proposition 65 requires that businesses notify California residents regarding potentially harmful chemicals (those that may cause cancer or reproductive harm) that can be found in their products. These warnings are intended to help consumers make informed decisions regarding the safety of the products that they purchase. To learn more about Proposition 65, please visit the California Office of Environmental Health Hazard Assessment website.

FINDING PRODUCTS FOR YOUR VEHICLE

In North America, most vehicles have the model year and engine size printed on an

emissions decal placed on the underside of the hood. Many vehicle manufacturers

display make and model emblems on the back or side of the vehicle. If you know your

make, model, year, and engine size, you can use K&N's application search to locate

compatible products for your vehicle.

Your vehicle identification number (VIN) can also be a quick and easy way to find

compatible K&N® parts for your vehicle. Your vehicle’s VIN is printed on a tag

located on the driver's side dashboard of your vehicle, and can be read from the

outside looking in through the windshield. The VIN is also located on a tag inside

the driver's side door jam or on the door itself. It is also listed on your vehicle

registration certificate. If you know your vehicle’s VIN, you can use K&N's vehicle

search by VIN tool to find compatible products for your vehicle.

In Europe, your registration documents detail your engine size and vehicle type.

However, if you do not know whether your vehicle is spi (single point injection) or

mpi (multi point injection), we suggest that you consult your local dealer. Once you

have found your vehicle's information, please use K&N's vehicle search bar up above

to find compatible K&N® products.

SHAPE

When fitting a conventional round filter on top of your engine—such as a carburetor,

central fuel injector, or throttle body fuel injector—a large diameter, short filter

will provide more airflow than a small diameter, tall filter. For example, a 10-inch

diameter, 2-inch tall filter will provide more airflow than a 5-inch diameter,

4-inch tall filter. Where space permits, the height of the filter should be between

1/5 and 1/4 of its diameter.

The shape of the filter is less important if the application calls for a remote

mounted filter, which includes many late-model fuel-injected vehicles. Typically,

these vehicles will use a flat panel filter, or a conical/cylindrical shaped filter

with a rubber mounting flange designed to be mounted on the end of the inlet hose.

SIZE

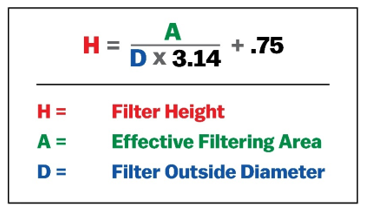

Use the formula below to compute the minimum size filter required for your particular application. The usable portion of the filter—the effective filtering area—is calculated by multiplying the diameter of the filter times pi (3.1416), multiplying by the height of the air filter in inches, and then subtracting .75-inch. We subtract .75-inch to compensate for the rubber seals on each end of the element and the filter material near them, since very little air flows through this area.

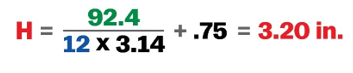

Example: A 350 CID Chevy engine with a horsepower peak at 5,500 rpm.

If you are sizing a panel filter, multiply the width of the filter area (not the rubber seal) by its length. If you are sizing a round filter, use the following formula to determine the height of the filter.

example:

Referencing the K&N vehicle search bar shows the proper filter for this application

would be an E-1500, which is 3.5 inches tall. Keep in mind, this is the minimum size

requirement. To provide an even greater volume of air to the engine, install the

largest filter that will fit in the space allotted.

Off-road conditions require additional filter surface area. A filter should be sized

1-1/2 to 2 times larger than normal for any conditions that could be considered

severe. In this case, the E-1500 used in our example should be replaced by an E-1120

or an E-1150. For long distance off-road events, two double-size remote mounted

filters would be recommended.

TROUBLESHOOTING

Please contact K&N® customer service by calling 800-858-3333 (North America) or emailing [email protected]. View complete contact information, including K&N’s mailing address and overseas information here.

While uncommon, it is possible that a check engine light may come on after installing a K&N® air filter or performance intake system—but this does not necessarily mean that there is something wrong with your air filter or intake system. Occasionally, the increase in airflow and lower restriction provided by a K&N air filter or intake system will uncover an existing mechanical or electronic issue in a vehicle. In rare cases, you may have a K&N product which was manufactured outside of its design tolerances, causing sensors in your vehicle to read data outside of their normal expected values. Please contact customer service if you have any concerns regarding your vehicle’s performance after the installation of a K&N product.

An unsubstantiated claim has circulated saying that K&N® oiled air filters can cause mass airflow sensors to fail. K&N has thoroughly investigated this claim, and has found no evidence to suggest that K&N filter oil is able to cause MAF sensor damage. Over the past several years, K&N has compiled data regarding MAF sensors sent in by consumers and dealerships, which you can view here.

With over 10,000 part numbers available, there is a very good chance K&N® has an existing product to meet your filtration needs. In the event we do not have an air filter available, you may look into the K&N Custom Filter Program.

K&N® AIR FILTERS

Typical disposable paper air filters function on a size-dependent basis, in which

dirt particles that are larger than the openings in the filter media are blocked,

while particles that are smaller than the openings can pass through. Most disposable

paper filters create more airflow restriction than K&N filters, as the openings in

the filter media have to be tiny in order to filter efficiently, which can reduce

airflow.

K&N® High-Flow Air Filters™ utilize depth loading, in which multiple layers of

pleated cotton fibers provide particle retention on many levels. However, while most

typical paper or foam filters would experience a large reduction in airflow when

designed for a dramatic increase in efficiency, High-Flow Air Filters™ are

specifically engineered to capture dirt while still allowing a high volume of

airflow to pass through.

Under normal circumstances, an increase in airflow to the engine also increases the efficiency of the combustion process, which can result in an increase in horsepower. K&N® High-Flow Air Filters™ are designed to provide high airflow in order to help increase engine performance.

Both airflow and filtration efficiency are critical to engine performance. Some companies design filters that provide high airflow by greatly reducing filtration efficiency, which can risk engine damage. K&N® filters are designed to provide high airflow while also maintaining exceptional filtration. As the appearance of K&N filters has become popular, many companies have started offering products that mimic the appearance of K&N filters, but do not provide the same level of quality and protection.

Micron ratings are typically used only for liquid filters. K&N® tests filtration efficiency and capacity using the ISO 5011 laboratory test procedure, and most K&N® air filters test between 97%-99% efficiency. Many K&N air filters have published test data included in the “Available Information” section of the product details page.

Laboratory tests utilizing ISO 5011 test protocols demonstrate that most K&N® air filters achieve overall filtration efficiency in the range of 97% to 99%. (The ability of an air filter to protect an engine is generally measured in accordance with laboratory testing procedure ISO 5011.) K&N® air filter designs are subjected to ISO 5011 testing involving coarse and fine test dust, and the test results are measured by a specific air filtration efficiency number. K&N® filters are designed to provide exceptional airflow while simultaneously targeting an overall filtration efficiency that meets or exceeds OEM standards.

No. Most disposable filters are "barrier filters,” which act as a physical barrier to dust particles. Once a dust particle covers a pore in the media, air can no longer flow through that space. K&N® replacement air filters are designed to absorb dirt and dust particles instead of physically blocking them, allowing the pores in the material to continue flowing air.

Most vehicles do not have a published minimum filtration requirement, as filtration needs will vary greatly among vehicles based on usage and other factors. However, K&N® filters are engineered to meet or exceed OEM standards.

K&N® does not make any claims or advertisements regarding fuel economy.

K&N® does not complete vehicle performance tests (dynamometer tests) for every application for which a replacement air filter is offered. Airflow testing is performed on every air filter design in order to verify that the K&N filter provides high airflow. However, other components of the vehicle's air intake system (like the air filter housing or tubing) can create air restriction and limit horsepower. The design of these parts varies among different vehicles and manufacturers, so there is no way to accurately estimate a specific horsepower gain from replacing an air filter alone.

Filter efficiency is only one element of filter performance. Capacity, restriction, and service life should also be taken into consideration when evaluating a filter. These other factors reflect the amount of dirt the filter can hold, how easily air can flow through the filter, and how long the filter can be used before servicing. A brick wall, for instance, would be likely to filter 100% of particulate matter—but would of course provide very limited airflow! K&N® filters are designed to strike a desirable balance between efficiency, capacity, durability, and airflow.

K&N® High-Flow Air Filters™ are designed to last for the life of your vehicle. If you assume an engine life of 175,000 miles—and replace your disposable air filter every 15,000 miles—only one K&N air filter will be used during the same period in which eleven disposable air filters are discarded.

While the oiled K&N® High-Flow Air Filter™ continues to be the most popular filter type among K&N® filter products, K&N also offers non-oiled synthetic DRYFLOW® air filters. The DRYFLOW® filter media is composed of two-layered synthetic material, which—much like High-Flow Air Filter™ media—provides depth loading properties. DRYFLOW® filter media provides slightly less airflow than High-Flow Air Filter™ media, though it is still designed to strike a desirable balance between airflow and efficiency, provide a high level of contaminant capture, and outperform typical disposable paper air filters in airflow. Because they do not have to be re-oiled, servicing DRYFLOW® air filters is typically a quick and easy process.

No. In the United States, in order for the manufacturer of a warranted product to void or deny warranty coverage of a repair due to the use of an aftermarket part, the manufacturer must provide proof that the aftermarket part is the cause of the necessary repair. These rights are protected under the Consumer Products Warranty Act of 1975 (also referred to as the Magnuson-Moss Warranty Act).

HOW TO CLEAN/SERVICE K&N® FILTERS

The service interval for a drop-in replacement K&N® High-Flow Air Filter™ can vary greatly depending on the severity of driving conditions—from 100 miles in a desert-racing environment to up to 50,000 miles under normal highway driving conditions. K&N replacement air filters that fit in the factory air box can go up to 50,000 miles before cleaning is required (under normal highway driving conditions), and the larger conical filters included with K&N air intake systems can go up to 100,000 miles before needing to be cleaned (under normal highway driving conditions). Follow this link to view complete cleaning instructions.

K&N® High-Flow Air Filters™ can be cleaned and re-oiled using a K&N Recharger® kit as often as is reasonably necessary. K&N drop-in replacement High-Flow Air Filters™ typically require servicing once every 50,000 miles under normal highway driving conditions, and the larger filters included with K&N intake systems can go up to 100,000 miles before needing to be cleaned (under normal highway driving conditions). Follow this link to view complete cleaning instructions.

Once you determine your K&N® DRYFLOW® air filter needs to be cleaned, K&N® air filter cleaning products help restore your air filter to like-new condition. There are specific cleaning kits available for non-oiled K&N filters. Follow this link to view complete cleaning instructions and available products.

When servicing your High-Flow Air Filter™, be sure to follow the re-oiling directions carefully. Use only K&N oil, and never saturate the filter. If oil drips from the filter, allow the filter to sit for several minutes until it stops dripping, and then wipe any excess oil from the filter frame. Follow the oiling instructions included in the Recharger® cleaning kit, and contact customer service if you have questions regarding the oiling process. For the required oil quantity by filter part number, enter the part number in the "Search by Part" box on our Application Search Page, and the factory oil amount will be shown.

Most K&N® cotton air filters come from the factory pre-oiled and ready to install. Certain specialty and racing filters are manufactured as un-oiled filters, and will be clearly indicated as such. Synthetic air filters (such as DRYFLOW® air filters) do not utilize filter oil. Please refer to the Product Specifications on the product details page for your air filter to determine if oil is required, or contact customer service.

K&N® does not recommend using other detergents or solvents to clean your air filter, and does not recommend applying any other type of oil. Products other than those manufactured by K&N® have not been tested and may deteriorate the performance and filtering ability of your air filter. Follow this link to view K&N® cleaning product options.

K&N® recommends against using compressed air to dry your air filter, as compressed air may rip and tear the filter fibers. Always allow the filter to dry naturally.

K&N® does not recommend the use of brushes to clean air filters, as the bristles from a brush may rip and degrade the filter media.

K&N® AIR INTAKE SYSTEMS

K&N offers a guaranteed increase in horsepower and torque for all K&N intake systems.

Dynamometer tests indicating estimated horsepower and torque increases compared to

the OEM intake system will appear on the "Product Details" page for each performance

intake system. Results will vary.

K&N® provides estimated SAE corrected horsepower gains that are based on actual

dynamometer testing for a specific or similar vehicle. The actual horsepower

increase a consumer will receive will vary depending on such things as vehicle

condition, fuel, weather, and other circumstances. It would be impractical to test

every possible vehicle configuration or year in which a particular engine may be

used; therefore, many of our estimates are based upon similar engine/vehicle/year

dynamometer testing that we believe to be representational for the vehicle listed.

No. In the United States, in order for the manufacturer of a warranted product to void or deny warranty coverage of a repair due to the use of an aftermarket part, the manufacturer must provide proof that the aftermarket part is the cause of the necessary repair. These rights are protected under the Consumer Products Warranty Act of 1975 (also referred to as the Magnuson-Moss Warranty Act).

K&N® cold air intake systems allow for increased airflow to your engine, which results in an increase in horsepower and torque.

K&N® performance air intake systems are designed to create a less restrictive path

for airflow to reach the engine by removing the stock intake tubing that can

increase restriction, and also by utilizing high airflow filter media.

In a K&N cold air intake system, air first passes through a performance air

filter—typically a High-Flow Air Filter™, and then passes through a specially

designed tubing system that helps provide a smooth path for airflow.

K&N offers several intake system options to cater to different aesthetic, ease of maintenance, and filter media preferences. All are protected by K&N’s famous 10-Year/Million Mile Limited Warranty.

Roto-Molded High-Density Polyethylene (HDPE) Intake Systems: 57-Series,

63-Series

High-density polyethylene (HDPE) rotationally molded tubes help increase the volume

of airflow to your engine, and provide a guaranteed increase in horsepower and

torque. These systems are paired with a washable, reusable High-Flow Air Filter™

featuring oiled cotton filter media, and the oversized, conical design allows you to

go up to 100,000 miles between filter services under normal highway driving

conditions. A custom heat shield or air box helps protect intake air from the high

temperature of your engine bay, and the entire system can typically be installed in

less than 90 minutes.

*Certain 57-series and 63-series intakes are designed to function with the

factory air box, and feature a panel filter paired with a custom roto-molded

intake tube.

Mandrel-Bent Aluminum Intake Systems: 69-Series, 77-Series

Mandrel-bent aluminum intake tubes help provide an increase in airflow to your

engine, and each 69-series and 77-series intake system offers a guaranteed increase

in horsepower and torque. These systems are paired with a washable, reusable

High-Flow Air Filter™ featuring oiled cotton filter media, and the oversized,

conical design allows you to go up to 100,000 miles between filter services under

normal highway driving conditions. A steel heat shield helps protect intake air from

the high temperature of your engine bay, and the system can typically be installed

in less than 90 minutes.

Blackhawk Induction™ Air Intake Systems: 71-Series Blackhawk Induction™ air intake systems feature an oil-free synthetic filter media, black powder-coated aluminum intake tube, and all-black components. The layered DRYFLOW® synthetic filtration media provides increased airflow and exceptional engine protection without requiring oil, and a steel heat shield helps protect intake air from the high temperatures of your engine bay. The system can typically be installed in less than 90 minutes.

K&N® does not make any claims or guarantees in terms of increased gas mileage with the use of K&N filters or intakes, due to a vast number of variables that can affect a vehicle’s gas mileage.

An internal combustion engine operates by burning a mixture of fuel and oxygen within the engine’s cylinders. The fuel injectors provide a precise amount of fuel, which combines with air delivered by the air intake system. A spark plug then ignites the volatile gas, creating an explosion that forces the piston downward—turning the crankshaft. The piston-moving force that’s created during the combustion cycle is what produces horsepower. K&N performance products are designed to increase the efficiency of your engine’s combustion process.

Once you determine that the filter included in your intake kit needs to be cleaned, K&N® air filter cleaning products help restore your air filter to like-new condition. There are specific cleaning products for each type of filter. Follow this link to view complete cleaning instructions and available products.

Maintaining the proper air-to-fuel ratio (AFR) is critical for engine performance, and relates to the amount of air versus the amount of fuel used by an engine for combustion. A correct, stoichiometrically balanced AFR produces combustion with perfect efficiency, excluding other factors. For gasoline engines, the theoretically perfect chemical ratio is 14.7 : 1—14.7 parts air to one part fuel. In effect, this means that an engine requires almost fifteen times more air than fuel for efficient combustion—which emphasizes the importance of providing a high volume of air through an intake system.

K&N® intake systems are not compatible with vehicles equipped with a body lift. A

body lift will raise the body and fenders of the vehicle above the engine and frame,

and since most K&N intake kits mount to both the engine and the fender, the lift

would move the mounting points needed to install the kit—possibly resulting in the

tube coming loose, coming into contact with the hood or other engine components, and

even breaking. In most cases, serious modifications would be required to make the

kit work, and such modifications would void the 10-Year/Million Mile Limited

Warranty.

*K&N intake systems are compatible with vehicles with a suspension lift

installed.

At this time, it is not recommended to install a K&N® intake system on a vehicle with a throttle body spacer. A throttle body spacer will move the opening of the throttle body away from its stock location. Since K&N develops intake kits on vehicles with a throttle body in the factory location, the addition of a spacer would add length to the intake tube, pushing it away from its mounting points—and possibly causing the tube to come loose, come into contact with the hood or other engine components, or even break. In most cases, serious modifications would be required to make the kit work, and such modifications would void the 10-Year/Million Mile Limited Warranty.

K&N® CABIN AIR FILTERS

Cabin air filters have become increasingly more popular, but some vehicles do not have cabin filters, so you will need to check your owner’s manual to determine if your vehicle has one.

Cabin air filters are used to filter the air that is coming through your vehicle’s HVAC system and into the interior.

Yes. Modern vehicles are sold with an air filter in the engine bay used to protect the engine from contaminants, and some have the addition of a cabin air filter used to filter the air entering your vehicle’s interior. While both types of filters trap contaminants, they are composed of different types of filter media and are not interchangeable.

Follow this link to view detailed cleaning instructions.

K&N® does not recommend using other detergents or solvents to clean your K&N cabin air filter, as doing so may damage the filter media.

Your K&N® cabin filter is sold pre-treated and ready to install.

Installing a high airflow filter may help reduce HVAC system strain, which can help preserve your heating/cooling system’s efficiency. Using a dirty or restrictive cabin air filter may put additional strain on your system.

K&N® LIFETIME WASHABLE HOME AIR FILTERS

Follow this link to select and purchase available K&N® home filters in your required size. If you aren’t sure of the size you need, you can examine your current HVAC filter for its dimensions, or measure your home air filter housing.

K&N® home air filters are manufactured at MERV 11 (minimum efficiency rated value). Filters rated at MERV 11 (according to the National Air Filtration Association) help filter dust, hair, plant spores, pet dander, mold spores, cement dust, insecticide dust, pollen, dust mites, bacteria, and tobacco smoke.

The frame is composed of durable extruded ABS copolymer, specifically designed to last for the long lifespan of the filter.

K&N® home air filters feature non-woven pleated synthetic filter media sandwiched between two nylon mesh screens for added structural support. The filter material is backed with a screen of galvanized mild steel mesh for added stability.

Static pressures frequently vary from unit-to-unit, as ducting and other factors aside from the filter can influence pressure readings.

Your individual cleaning interval will depend on home conditions—including the number of occupants and pets in your home—but should generally range from 60 to 90 days. If you have multiple pets or allergy-sensitive people in your home, it is advisable to clean your filter more often.

Cleaning is usually quick and easy. Please follow this link to the detailed cleaning instructions.

Your K&N® home air filter is designed to be washed and reinstalled as often as reasonably necessary.

Installing a clean filter can help reduce HVAC system strain and may require less energy than a more restrictive or dirty filter. K&N® home air filters are washable and reusable, allowing you to restore your filter’s performance quickly and easily.

Yes. As part of the manufacturing process, the filter media is electrostatically charged for additional particle capturing capability.

Yes, they are protected by K&N’s Lifetime Limited Warranty.

In keeping with industry standards, each filter is manufactured slightly smaller than the dimensions shown on the box, allowing room for hardware and register size variances.

K&N® OIL FILTERS

Yes. K&N® oil filters are compatible with conventional, synthetic, and blended motor oils.

Each K&N® oil filter is designed to meet or exceed OEM specifications for efficiency, and each design is laboratory tested for efficiency, capacity, and burst strength.

K&N® oil filters are designed to withstand the longer service intervals that some vehicle manufacturers now recommend. Please follow your vehicle manufacturer’s recommendations for oil filter replacement.

No, the nut on Wrench-Off® oil filters cannot be used for installation, as doing so may cause serious damage to the filter. If you attempt to use the nut to tighten the filter on installation, you may end up over-tightening the filter or causing damage to the spot welds on the filter—which could result in cracking and leakage while the filter is in service. The nut is intended to be used for convenient removal only.

BOOST CONTROL MODULE

The Boost Control Module works within factory parameters to increase boost and improve throttle response.

The Boost Control Module instructs the vehicle’s ECU to increase the amount of pressure in the manifold to a higher level before releasing it through the wastegate, which keeps additional boost available for increased horsepower.

The K&N® Boost Control Module can typically be installed in less than 60 minutes with no software required.

Yes. The kit includes a dial (where applicable) which is engineered to be installed in-cab, and can be adjusted while on-the-go.

The kit includes the module, wiring harness, adjustable knob (where applicable), hardware, and detailed instructions.

The Boost Control Module is covered under K&N’s 90-Day Limited Warranty.

Yes. The Boost Control Module is compatible with other performance upgrades, including exhausts, intake systems, larger turbos, and more.

The Boost Control Module provides an estimated power increase of up to 46 horsepower and 59 lb./ft. of torque. Estimated horsepower and torque gains based on specific or similar vehicle dynamometer tests. Results will vary.

THROTTLE CONTROL MODULE

The K&N Throttle Control Module is designed to improve throttle response and acceleration, and improves pedal sensitivity without modifying factory ECU settings.

The system processes input data from the gas pedal, and modifies the signal before sending it to the ECU for an adjustable level of sensitivity—creating an increase in throttle responsiveness.

The K&N® Throttle Control Module can typically be installed in less than 30 minutes with no software required.

Yes. The kit includes a dial which is engineered to be installed in-cab, and can be adjusted while on-the-go.

The kit includes the module, wiring harness, adjustable knob, hardware, and detailed instructions.

The Throttle Control Module is covered under K&N’s 90-Day Limited Warranty.

EXHAUST SYSTEMS

K&N® exhaust systems are engineered to increase horsepower and torque, and provide a more aggressive engine sound.

K&N® exhaust systems are composed of 304 stainless steel tubing. Some applications incorporate a polished stainless steel tip.

K&N® exhaust systems can typically be installed in less than 60 minutes utilizing factory mounting points, with no welding required.

K&N® exhaust systems are available in both cat-back and axle-back configurations depending on the vehicle application.

Yes. K&N® exhaust systems pair with most aftermarket modifications, including intake systems, boost control modules, throttle control modules, and more.

Dynamometer tests indicating estimated horsepower and torque increases compared to

the OEM intake system will appear on the "Product Details" page for each performance

exhaust system. Results will vary.

K&N® provides estimated SAE corrected horsepower gains that are based on actual

dynamometer testing for a specific or similar vehicle. The actual horsepower

increase a consumer will receive will vary depending on such things as vehicle

condition, fuel, weather, and other circumstances. It would be impractical to test

every possible vehicle configuration or year in which a particular engine may be

used; therefore, many of our estimates are based upon similar engine/vehicle/year

dynamometer testing that we believe to be representational for the vehicle listed.

K&N® exhaust systems are protected by K&N’s 1-Year Limited Warranty.

K&N® exhaust systems are engineered to improve the quality (“growl”) of the engine sound, while not significantly increasing decibel output.